We are an ISO 9001:2015 Certified Company. Our headquarters is located in Mulund, Mumbai. The manufacturing facility is spread over four acres of land in Khopoli, Raigad. The plant has been equipped with modern machinery and a skilled workforce with an installed capacity of 24000 MT wire processing per annum.

With Modern Technology and expert human resources, there is continuous innovation and expansion in our product offerings.

With years of knowledge and research in chemical metallurgy, we have developed surface processes that will result in improved quality wires.

The pickling process removes impurities, rust, and scale from the surface of the material.

Phosphate coating is applied over steel wire that creates a thin lubricate adhering layer of zinc phosphate that helps to do smooth wire drawing.

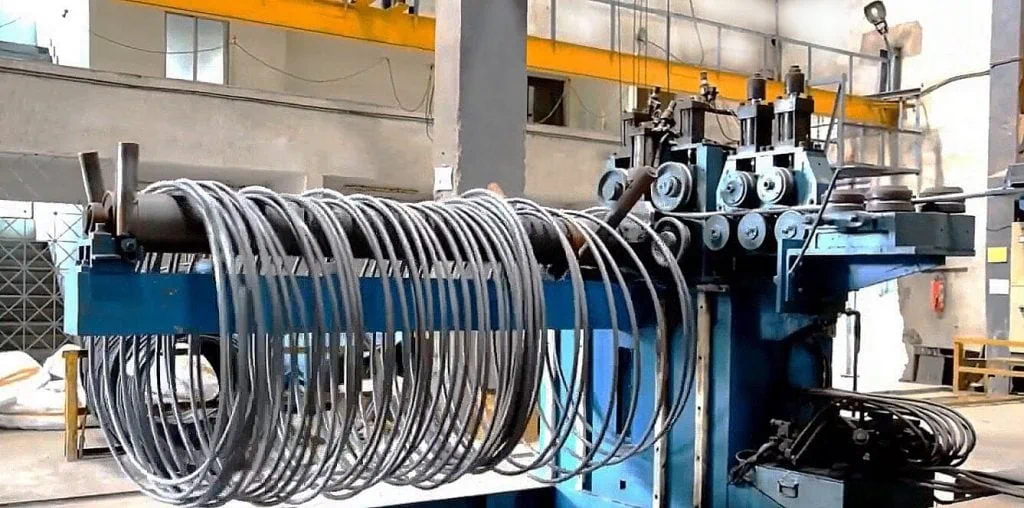

The Unit has fifteen advanced wire drawing machines. Each machine processed a different wire diameter and quantum. All the machines are operated by an experienced operator.

SWPL proudly introduces 1st time in H2 Spherodise Annealing in INDIAN Wire industry. This enables us to supply HIGH-QUALITY SAIP Wires & meet stringent norms such as:

We have metallurgical experts and experienced engineers in Quality inspection departments. All the testing equipment is timely calibrated.

Mechanical quality tests that are performed on CHQ wires, such as:

Tensile Strength Test: UTM is used to determine the yield strength of a steel wire. Test samples have been prepared as per ASTM standards. The tensile strength test provides a safe limit of loading, ductility and elongation of the steel wire.

Grain structure evaluation: Electronic microscope is used to see grain structure. Test samples have been prepared as per ASTM standards. This will help to check the effectiveness of heat treatment on grain structure.

Hardness Test: The Rockwell hardness tester machine indicates surface hardness by determining the depth of penetration of the indenter under a known load.

Chemical Composition Test: The computerized spectrometer is used to derive the chemical composition of the steel.

Finish coil is organized as per the customer’s requirement of coil weight, external and internal coil diameter. For packaging, we offer HDPE wrap, Gunny bag packing and jute wrapping. Wooden pallet packing can also be done on demand.

For dispatch and packaging separate area is allotted. We are authorized by customs for export cargo stuffing at the factory premise.

Copyright © 2024. All rights reserved. Syscon Wires Pvt. Ltd.

Desiged by XENRION