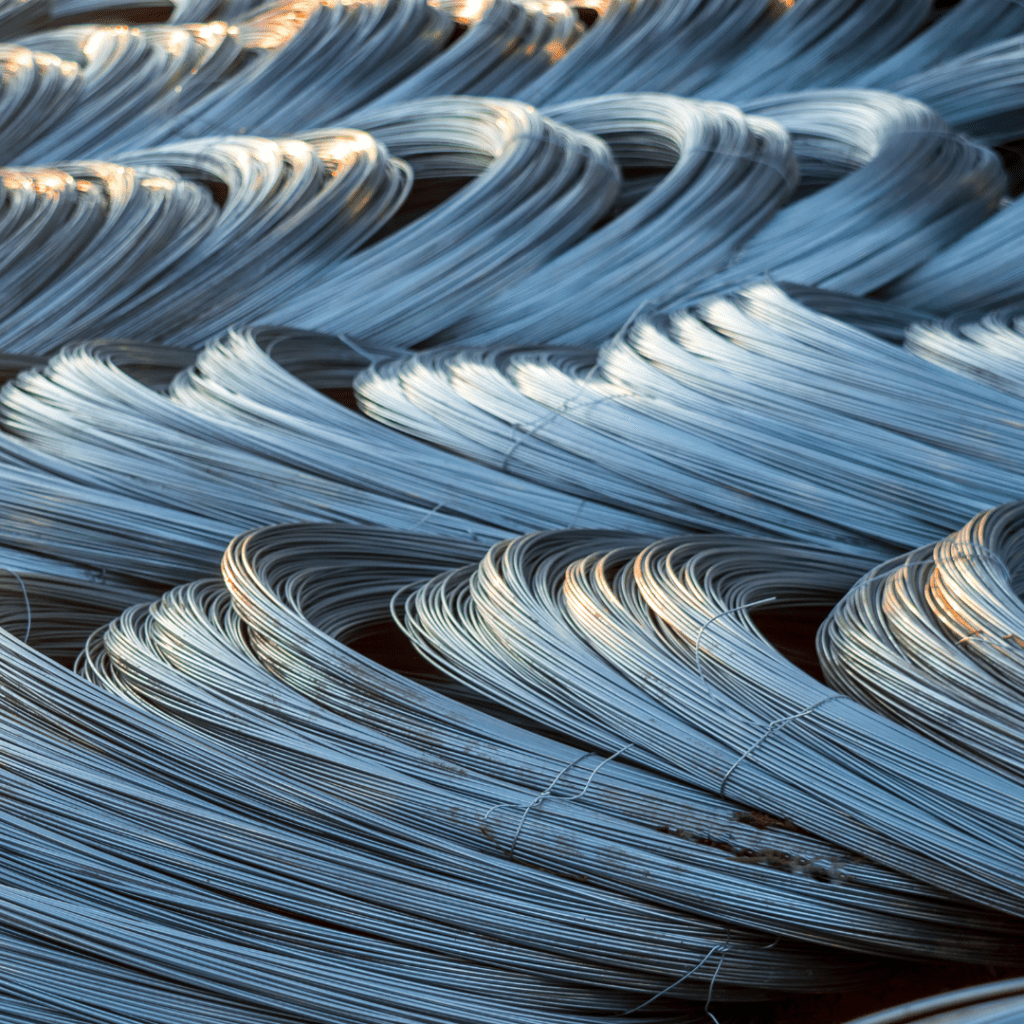

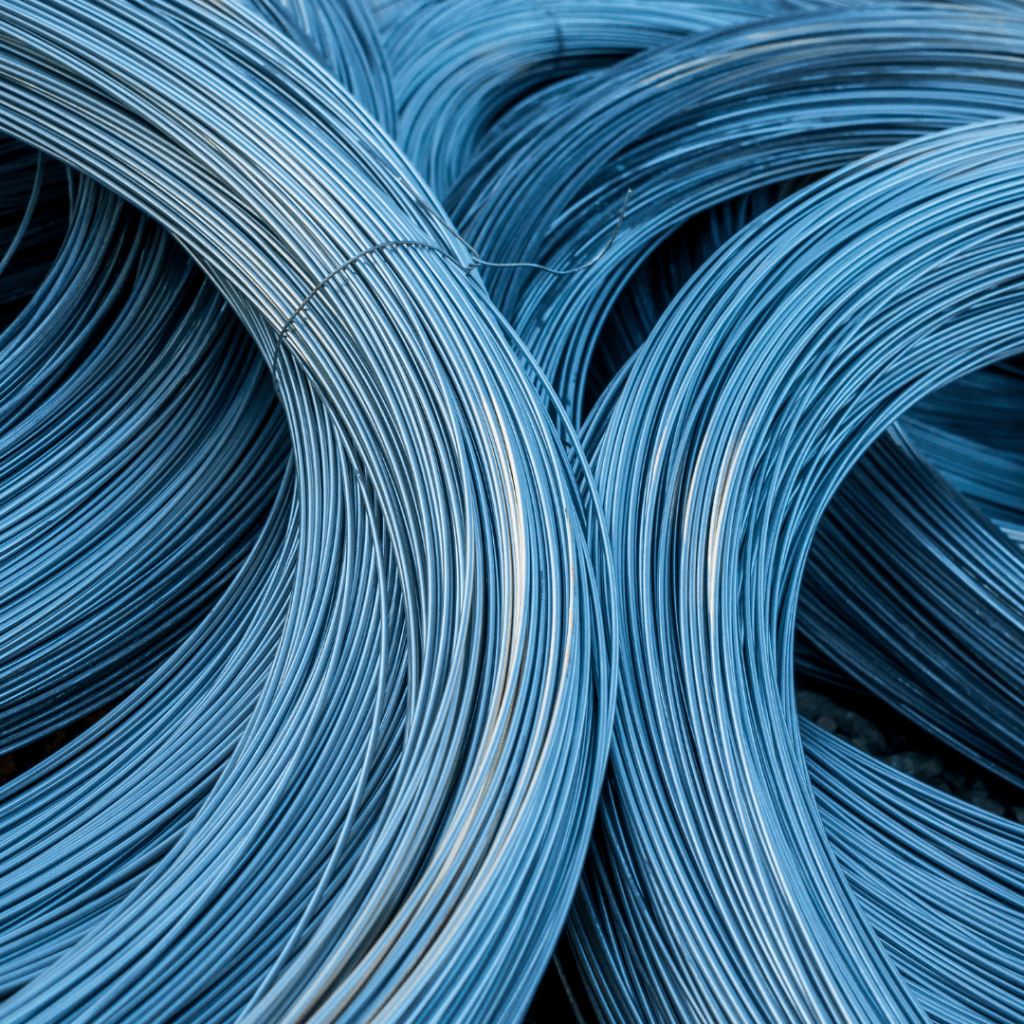

We manufacture a range alloy steel wires that are made from finest grade of steel with international standards and norms.

We are engaged in offering superior quality Alloy Steel Wires. We offer these wire products in different sizes, finishes, dimensions to meet the diverse requirements of our esteemed customers.

1. What is alloy steel wire and what are its uses

Alloy steel wire is a type of steel that contains other alloying elements in addition to carbon. The most common alloying elements include manganese, chromium, nickel, molybdenum, and vanadium. Alloy steel wires are used for various applications such as springs, fasteners, and cables.

2. How is alloy steel wire made

The process of making alloy steel wire begins with melting the raw material in an electric arc furnace. This is followed by adding the desired alloying elements and casting the molten metal into ingots. The ingots are then hot rolled into wire rods which are further made into wires of the desired thickness and hardness.

3. What are the benefits of using alloy steel wire

Alloy steel wires offer a number of advantages over other types of steel wires. They are stronger and more durable, and can withstand higher temperatures. They are also more resistant to corrosion and wear. Additionally, alloy steel wires can be custom-made to meet the specific needs of the application.

4. How is alloy steel wire used

Alloy steel wire can be used for a variety of applications such as springs, fasteners, and cables. It is also often used in the construction of buildings and bridges. Additionally, it can be used in the manufacturing of cars and other vehicles.

5. What are the challenges associated with using alloy steel wire

One of the challenges associated with using alloy steel wire is that it can be more expensive than other types of steel wire. Additionally, it can be difficult to find a supplier that offers custom-made wires to meet the specific needs of the application. However, the benefits of using alloy steel wire usually outweigh the challenges.

5. How to select the right alloy steel wire for your needs

When selecting alloy steel wire for your needs, it is important to consider the specific application and the desired properties of the wire. Some of the things that you will need to take into account include the strength, durability, resistance to corrosion and wear, and the ability to withstand high temperatures. You will also need to consider the cost of the wire and the availability of a supplier that can provide custom-made wires.

6. Tips for working with alloy steel wire

If you are working with alloy steel wire, there are a few things that you need to keep in mind in order to ensure that the job is done correctly. First of all, it is important to wear gloves and other protective gear to avoid injury. Second, you need to be careful when cutting or shaping the wire as it can be very sharp. Finally, it is important to clean the wire before use to remove any debris or dirt.

7. Tips for using and caring for alloy steel wire products

If you are using alloy steel wire products, there are a few things that you need to keep in mind in order to ensure that they last for a long time. First of all, it is important to follow the instructions carefully and avoid overbending or stretching the wire. Second, you need to regularly clean the wire and remove any dirt or debris. Finally, it is important to inspect the wire for any signs of damage and replace it if necessary.

8. Applications of alloy steel wire in various industries

Alloy steel wire has a wide range of applications in various industries. In the automotive industry, it is used in the manufacturing of cars and other vehicles. In the construction industry, it is used in the construction of buildings and bridges. Additionally, it can be used in the production of electrical cables and springs.